A Biased View of Motorcycle Parts New Zealand Specialists

Wiki Article

Everything about Motorcycle Parts New Zealand Specialists

Table of ContentsSome Of Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Things To Know Before You Get ThisSee This Report on Motorcycle Parts New Zealand Specialists5 Easy Facts About Motorcycle Parts New Zealand Specialists ShownHow Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.Motorcycle Parts New Zealand Specialists Fundamentals ExplainedThe Of Motorcycle Parts New Zealand SpecialistsA Biased View of Motorcycle Parts New Zealand Specialists

So, reach out to one of our professionals today.CNC machining modern technology is swiftly coming to be the prime focus of several production procedures around the globe as a straight outcome of its numerous benefits over other methods. In addition, the markets that manufacture motorbikes have hopped on board with this fad. One of the most cutting-edge firms are currently developing their engine elements and wheels using machining techniques initially created for motorbike components.

You may be asking yourself why we use. Currently that we have your interest allow us clarify the reasoning behind this modern growth in the motorbike production industry.

Indicators on Motorcycle Parts New Zealand Specialists You Need To Know

On top of that, you have total control over the appearance of the elements, even down to the min information. Occasionally, motorcyclists may make a decision to improve their experience by setting up aftermarket parts or customizing the bike's transformation. When once again, computer system numerical control (CNC) machining is one of the most functional approach. Upgrades might be of any kind of type and design you want.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

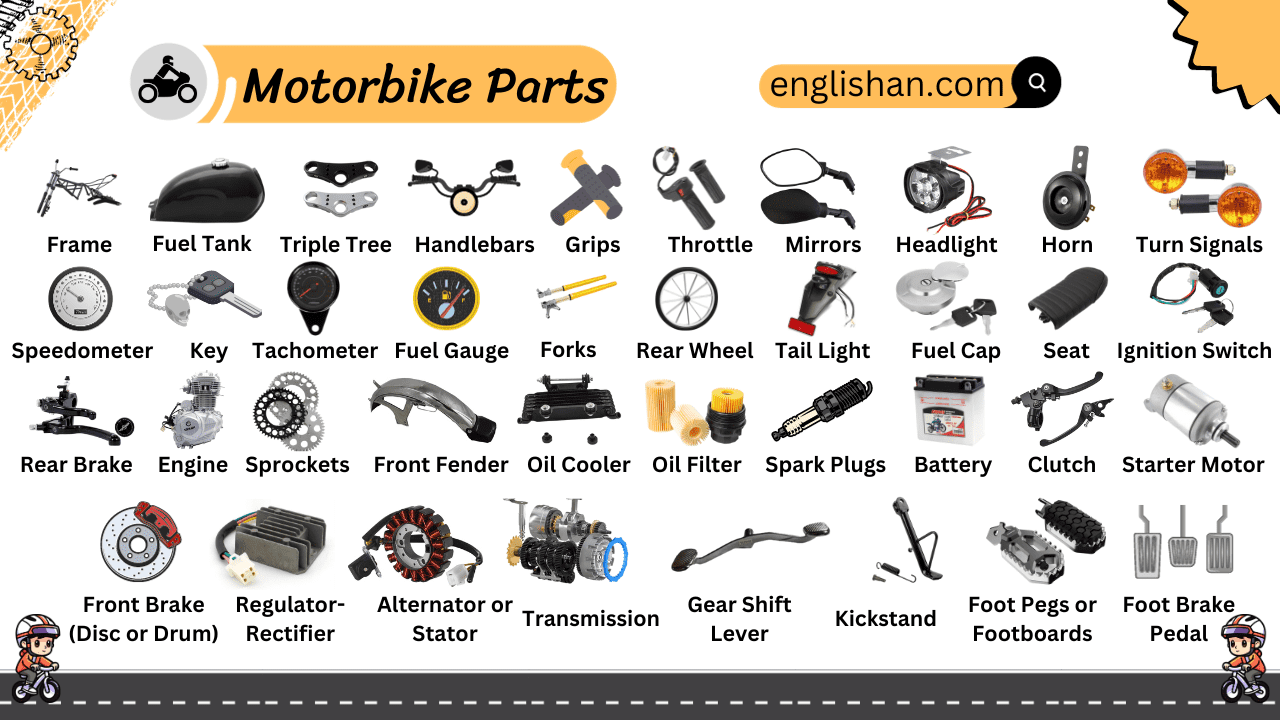

CNC machining may be utilized to make nearly all of a motorcycle's steel and plastic elements. To continue, we'll review a number of machined parts for bikes.Milling procedures are made use of to acquire the preferred degree of wheel customization. An additional aspect of the motorbike that may be customized is the tires.

Not known Incorrect Statements About Motorcycle Parts New Zealand Specialists

When it concerns a car (or a motorcycle), the most important element is the engine. A number of people mention it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons often tend to be intricate and call for layouts with a high degree of precision.Use just high-quality products, nevertheless, since these lights are vital for the safety of motorcyclists and various other chauffeurs or people on the road, particularly at night. Motorbike fronts lights have three primary components: the light bulb, or light resource, the lens, and the housing.

Milling processes with a remarkable finish would cause the lenses having a reflective top quality that resembles that of a mirror. The cover, on the various other hand, is not composed of vulnerable products; instead, it is constructed out of tough polymers that can be machined right into even more elaborate patterns.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered

Bike suppliers typically cast these elements, yet only for the production of bespoke components. Machining on 5 axes in today's globe is the means by which any type of style shape might be recognized.Continued Pick Runsom for your personalized bike components! We have the ability to make challenging and elegant elements making your bike matchless.

Here are a few examples of metals commonly utilized in motorbike element machining. Aluminum is the main material utilized by firms specializing in generating customized motorbike elements to develop the majority of these parts. In the past, we would build our engines out of actors iron. On the other hand, light weight aluminum is promptly ending up being the material of choice, partly because of the truth that it is a lot more light-weight.

Zinc describes an additional steel that is very light in weight and has excellent machining qualities because of its high mechanical strength. This product might be formed into nearly any kind of form and maintains its measurements well. Also mission-critical parts that need a high level of accuracy might take advantage of their use.

The Definitive Guide for Motorcycle Parts New Zealand Specialists

Another metal that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest steels that are now obtainable and has excellent machinability features and weblink strength compatible with its low weight. One of the disadvantages of magnesium is that its dust may quickly capture fire.

Their most common usage in generating various bike parts is bolts, such as screws and screws. Their low susceptibility to oxidation and deterioration makes them suitable for this use.

The Definitive Guide for Motorcycle Parts New Zealand Specialists

It seems that CNC transforming and grating are the fundamental processes. Nonetheless, alternate methods exist, such as exploration. Let's explore a lot of these machining techniques comprehensive. The CNC turning method is thought about a subtractive manufacturing technique. Additionally, it calls for maintaining bars of Learn More Here product, frequently plastic or metal, in position and then twisting a cutting tool to eliminate sections of the material as the material is turned.

These techniques are just as important and generate parts with high precision and regular high quality. They are respectively: grinding, laser cutting, and drilling. The term "surface area coating" refers to post-processes after the initial machining phase. Motorcycle Parts New Zealand Specialists. The processes help boost the overall quality of the machined bike elements. Below are the quick intro, benefits and drawbacks of 5 surface treatment methods.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

Report this wiki page